- Cutting is done with a vibrating 3x0,6 mm toothed knife in machine.

- Without limiting at the endless round of ability in turn cuts can be achieved without problems.

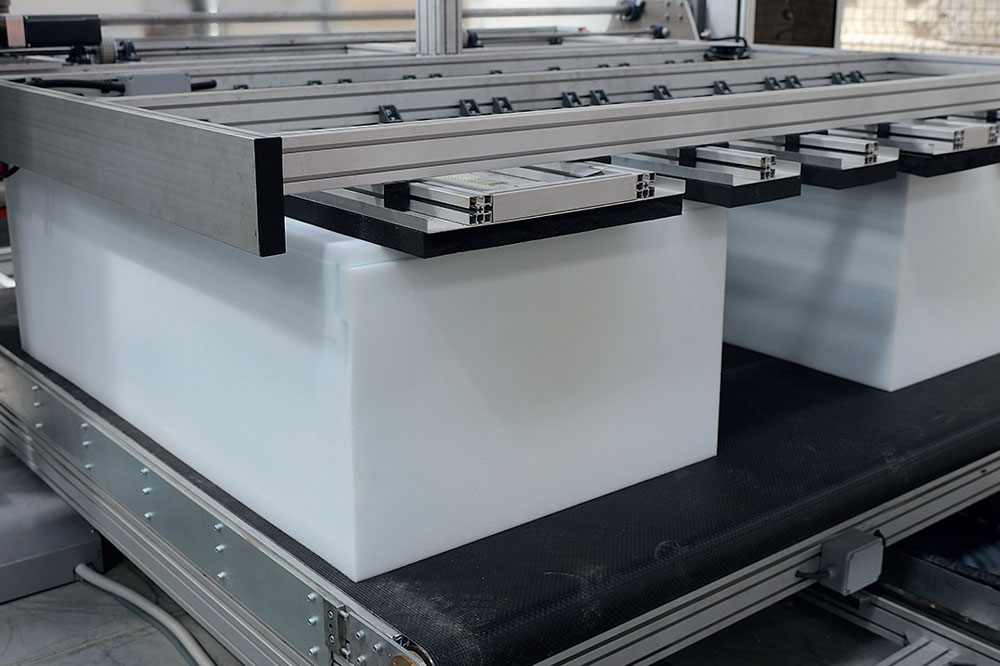

- The machine loads the block cutting area automatically.

- The cut foam block can be discharged by means of conveyor automatically.

- Cutting quality is ensured with the top pressure faeture.

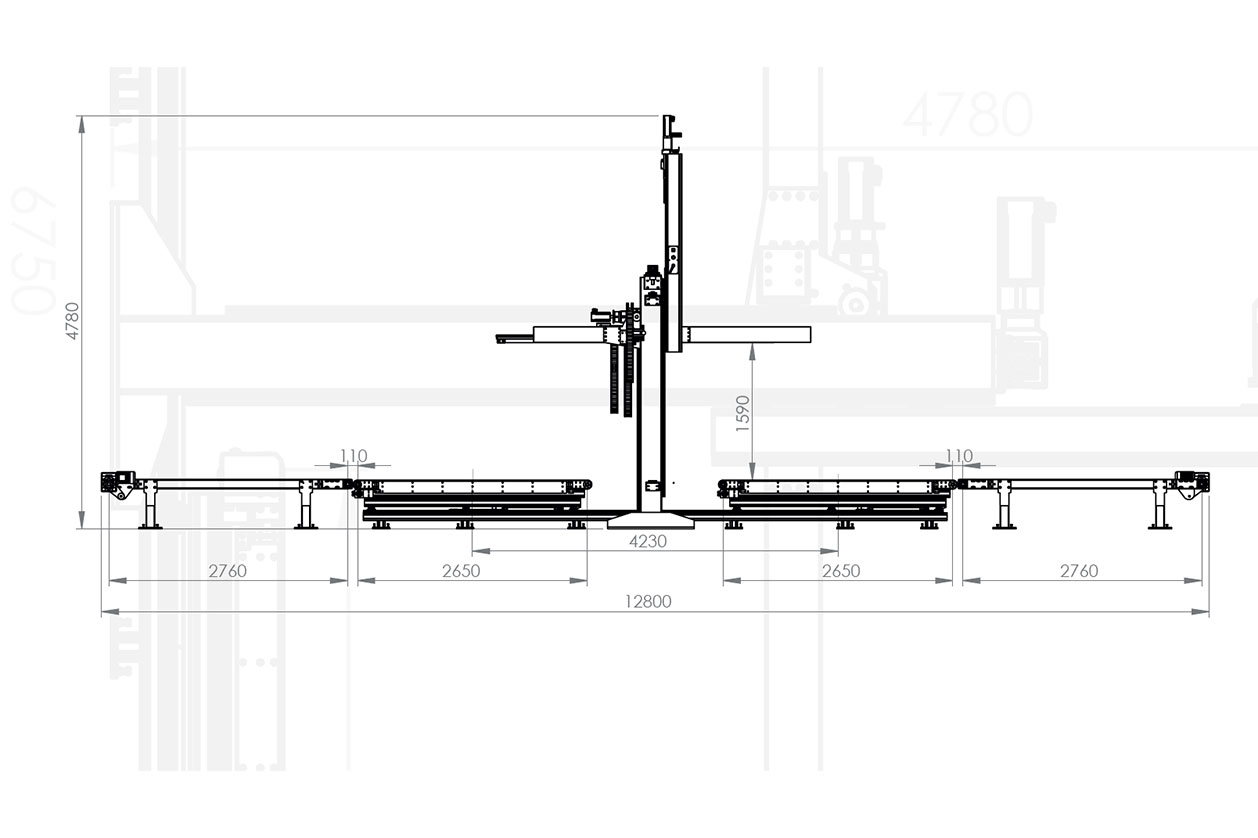

- Top pressure and table is working in synchronous. - Tabla with the feature of Rotary Table 0 - 90 degrees of rotation provides the possibility of making a double cut..

- Vibration is minimized thanks to supporting knife feature.

- With the SableNEST drawing program can be made quick and easy cutting programs

- Safety equipment is designed according to category 4 and senior security measures are presented.

- With voice and light warning system to start programs, operations and ending transactions are stated clearly.

- The foam cutting rotation is showned on the screen of the operator panel.

- Cutting speed can be adjusted with the speed bar on the operator panel.

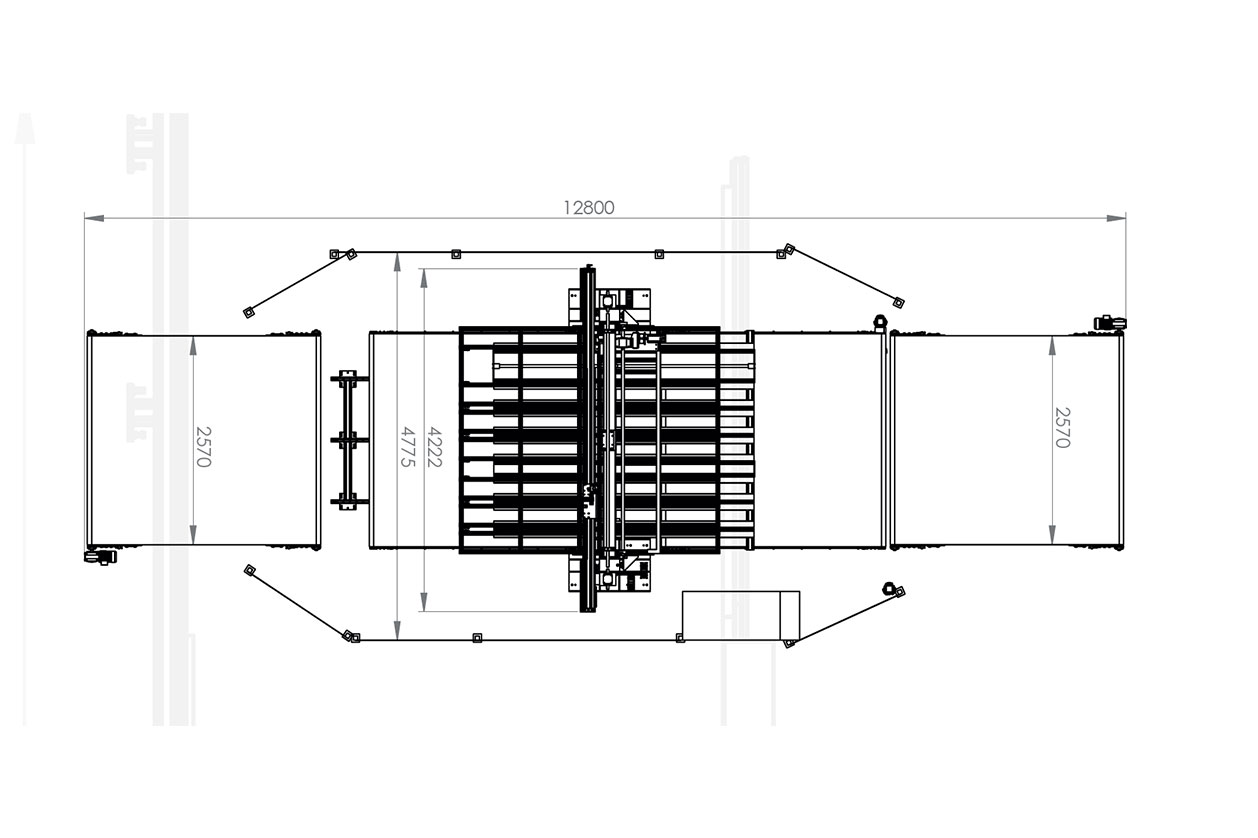

- It can be positioned and operated small area in terms of space-saving.

- This machine can cut PUR( polyurethane foams) like HR, CMH, and VISCO

| Cutting Height | 1500 mm. |

| Cutting Widht | 2500 mm. |

| Block Length Max. | 2700 mm. |

| Cutting Speed Max. | 15 m./min |

| Air Pressure | 6 bar |

| Power | 15 kW. |

| Option | Loading and unloading conveyor SableNest software Turn table with conveyor belt |